Materials

To Foil or Not to Foil: The Sustainable Truth of Metalized Decorating Techniques

Many want to conclude that all metalized effects are non-sustainable. It’s not true.

Published

14 years agoon

By

BXP StaffRECENT PRESENTATIONS and editorials in the press on sustainable packaging have been very quick to assemble all metalized decorating techniques into one category. In addition, it seems that there are many who want to conclude that all metalized effects are non-sustainable and always an environmentally unfriendly choice for brand managers and packaging designers.

Through the collaboration of several experts and business associates within the foil and film laminate industries, a list of several “myths” that have been rising up throughout the sustainable community have been addressed, accompanied by the true “realities” as they pertain to the use and the recyclability of metalized decoration.

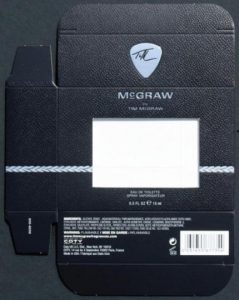

Metalized decoration technique on packaging for a scent from country singer Tim McGraw.

Myth: All metalized decorating should be categorized together. It is all basically manufactured and converted the same.

Reality: There are several different types of metalized decorating processes and several ways to apply a metalized surface to board or paper. Hot stamping foil contains a very thin layer of vacuum metalized aluminum on a polyester film carrier that is applied through a foil stamping or cold foil transfer process. The unique feature of hot stamping foils is the ability to transfer foil only in certain areas on the board or paper versus a complete transfer of the metalized product on the entire substrate.

Film and foil laminates also exist that are laminated to board or paper as a finished material before other printing or converting processes are done. In addition, there are transfer-metalized products where the metalized effect is transferred to the board or paper and the film is used as a carrier and is not transferred to the substrate, similar to the application of hot stamping foils.

AdvertisementThese types of metallic products include a very thin layer of metalized aluminum that literally would dissolve in a person’s hand. A fourth product includes wide-web aluminum foil laminations, which are used exclusively in decorative packaging, labels, and scratch-off lottery ticket applications.

All of the above are available in metallic silver, gold, and other metallic colors, as well as in specialty products such as brushed finish and holographic effects. Finally, metalized films that are utilized in flexible packaging applications are an entirely different product and process and should never be categorized with the use of metalized decorating through foil or foil laminates as described above.

Myth: All types of metalized decorating processes are non-recyclable and should not be considered a sustainable choice by brand mangers and packaging designers.

Reality: As described above, not all metalized decorating processes should be categorized together. The Foil & Specialty Effects Association (FSEA) has recently published a report that confirms the recyclability and repulpability of foil-decorated paper and paperboard. A well respected, third party research firm, Pira International in Surrey, England, performed the study. The study validates the recyclability of paper products decorated by both the hot stamp and cold foil processes.

A de-inking process removes the foil, film laminate, or transfer metalized material from a paper or board substrate. Companies that manufacture and supply film and foil laminated board have had the ability to recycle scrap for many years using a de-inking process that separates the laminate from the board. Then the fiber in the board is recaptured and sold for secondary market pulp.

Myth: Other emerging technologies that offer metallic effects are more sustainable than foil or film-laminated materials and provide the same graphic enhancement benefits .

AdvertisementReality: The incredibly small amount of aluminum that is utilized in vacuum metalized products such as foil laminates or hot stamping foils is very insignificant. And, as stated above, a specific study has confirmed the recyclability and repulpability of foil-decorated paper and board.

From a product enhancement standpoint, other metallic substitutes do not measure up to the true brilliance that vacuum metalized products such as hot stamping foils and foil (film) laminates deliver. With the space on retailers’ shelves becoming more and more valuable, the need for effective eye-catching, environmentally friendly packaging has never been more pressing.

These types of products generate visual energy unmatched by any other graphic medium. It is a great way to capture consumers and maintain sustainability. Foils and film laminates also provide far more design options than other metallic substitutes through combining opaque and transparent inks together over the silver, brushed, or holographic metallic surface. These types of combinations can add a great deal of perceived value to the finished package and can help differentiate it on the store shelves without sacrificing sustainability gains.

For more information on the Pira International study on the recyclability and repulpability of foil-decorated paper and paperboard, contact the Foil & Specialty Effects Association at 785-271-5816 or email jeff@fsea.com. Contributors to this article include Jeff Peterson, Foil and Specialty Effects Association (www.fsea.com ), Bob Hazen, Hazen Paper Company (www.hazen.com ), and Jim Parker, Brushfoil – Division of Interfilm Holdings Inc. (www.brushfoil.com ).

BXP elevates the value of innovative and collaborative brand package design as a strategic business competence across the omni-channel path to purchase, to ultimately help consumer facing and retail brands deliver more relevant experiences that connect with shoppers, win at shelf, own the moment of sale and maximize brand loyalty.

SPONSORED VIDEO

Branding with Ferocity – Thinking Like an Indie Brand

Get a better understanding on how to leverage new technologies to engage and delight shoppers, sustainability’s role in product and package design – being sustainable and premium are not mutually exclusive, plus best practices and tips for collaboration and how to launch new products and refresh existing product line-ups and brands.

You may like

Advertisement

GO MINIMALISM . . . HOLD ON A MINUTE!

Sustainable, 100% Recycled Transparent Sheeting is Now a Reality!

Kroger, Walgreens to Dedicate Section of Their Stores to Reusable Packaging

6 Marketing Tips for Ecommerce Brands to Win the Holiday Shopping Season

New Wunderoots Branding Celebrates the Carrot

Fact or Fiction? The Truth about Eco-Friendly Packaging

BXP May 2021 Think & Clink

Unilever Raises Bar for Accessibility with Degree Inclusive

Crown Royal’s Limited-Edition Pack Designed by Oscar-Winner

Coca-Cola Explores World of Paper Bottles

Subscribe

BULLETINS

Get the most important news and business

ideas from BXP Magazine's news bulletin.

Latest Tweets

Advertisement